When we purchase solar lights, particularly when buying solar street lights for government projects,there are a few common misunderstandings that can lead to mistakes. Some misunderstandings arise from the customers’ lack of understanding, while others are deliberately created by suppliers to confuse customers.Suppliers want to receive orders from customers while also making sufficient profits.

However, most customers end up encountering issues with the solar street lights they purchase. That’s why we have compiled a list of 7 misunderstandings to watch out for when purchasing solar lights. We also provide technical explanations for these misunderstandings.

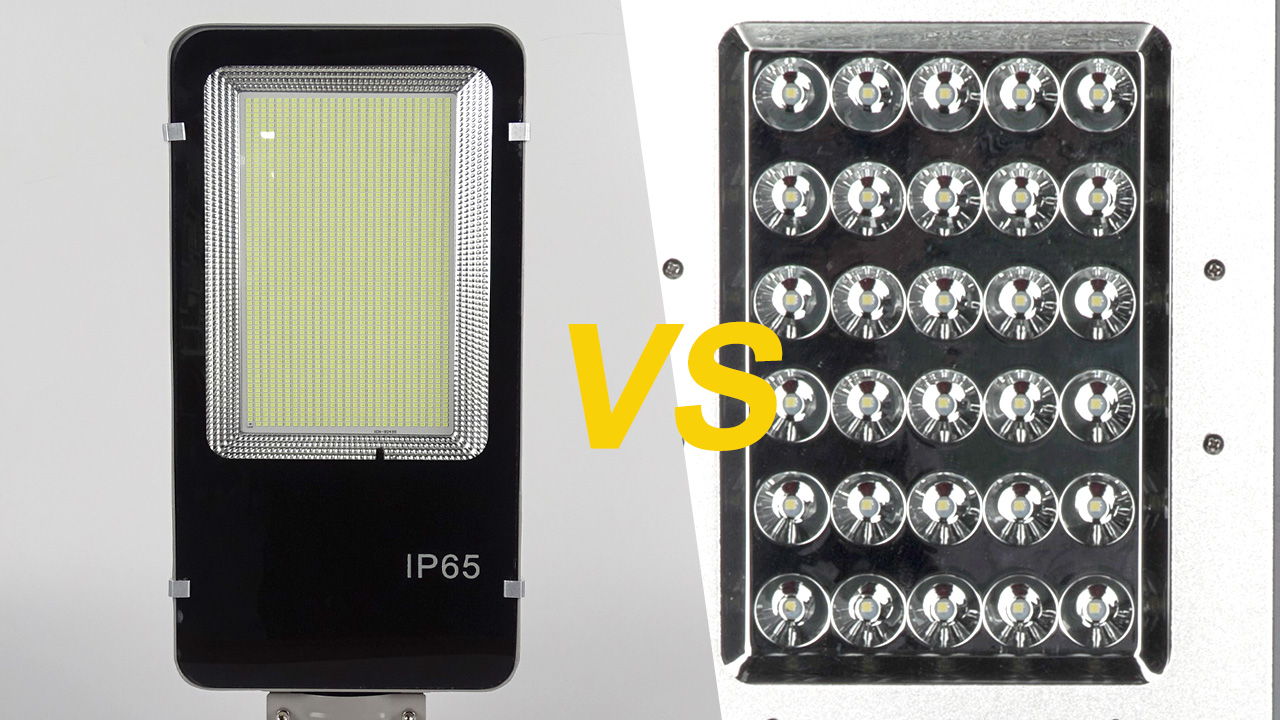

Misunderstanding 1: Led quantity is equal to led power

One common misunderstanding is that the number of LEDs in a solar light is equal to its power. However, this is not true. The power of an LED chip can range from 0.2 watts to 5 watts or more, regardless of how many LED chips are in the light. For example, the 2835 SMD LED chip is 0.2 watts, while the Phillips 3030 SMD is designed to be 0.3-1 watt, and the Phillips 5050 SMD can be set to 5 watts per piece at the highest.

Additionally, the price of LED chips from different brands can vary widely, from $0.002 to $0.2 per chip, for example. This means that the number of LEDs in a solar light is not an accurate indicator of its power or its cost. This misunderstanding is especially common in China when it comes to bidding on solar street light projects, where a certain number of LEDs is often required in the specifications.

It’s important to keep in mind that the number of LEDs does not necessarily mean more power or better quality.

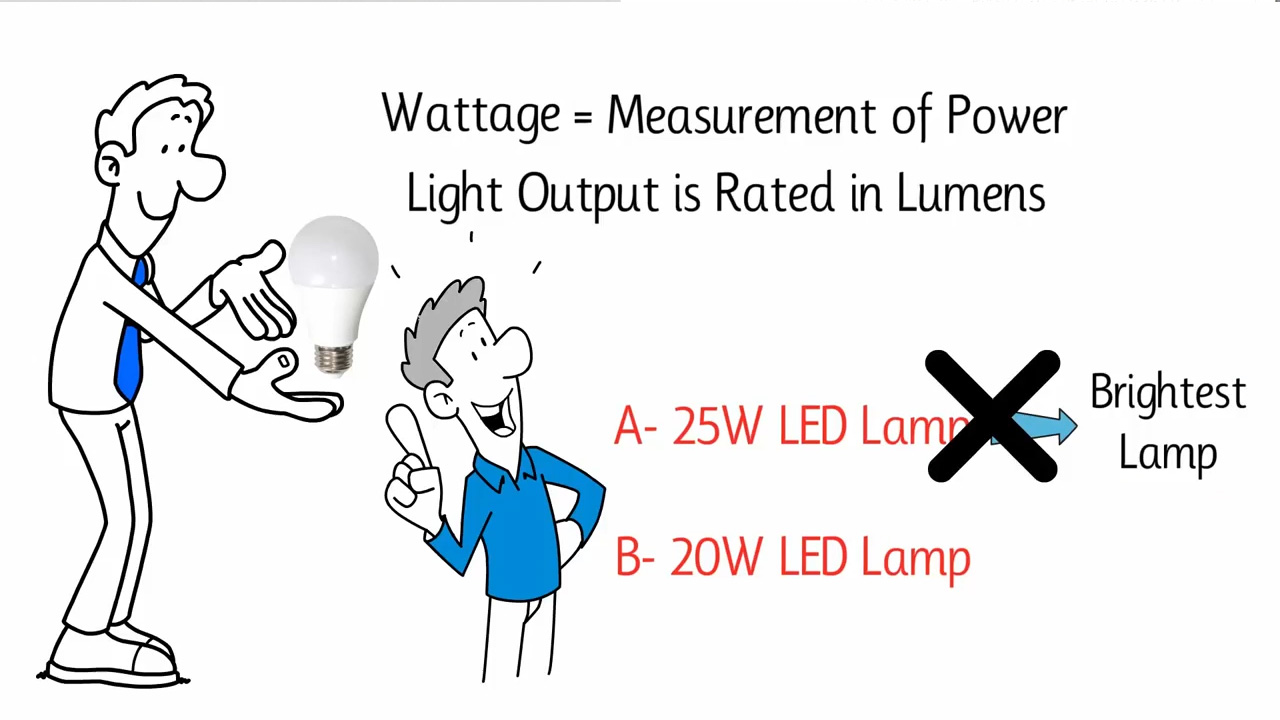

Misunderstanding 2: LED power equals brightness

One common misunderstanding is that the power of the LED determines its brightness. However, the third-generation light source LED can save more power while producing the same amount of brightness. Instead of measuring the brightness by the wattage, we should use lumens (lm) which is determined by the luminous efficacy (lumens per wattage) of the LED. For example, the luminous efficacy of electric incandescent lamps is only 12-24 lumens per wattage, whereas LED lights fixtures in 2020 can generate different luminance efficacy ranging from 130lm/w to over 200lm/w.

Therefore, it is important to calculate the brightness of solar lights by lumens rather than LED power. Many solar lights are labeled with higher LED power than their actual power. For instance, a 300-watt solar flood light may only have a real LED power of 15 watts. It is impossible for a small power solar panel to support high-power LED lighting for a long time, and the 3.2 voltage battery can only support LED power of up to 20 watts. Thus, when dealing with serious solar street light projects for government, it is crucial to consider not only the LED power but also the luminous efficacy of the entire solar light fixture.

Misunderstanding 3: Judging charge controller quality by current alone

Many people think that the current capacity of a solar charge controller is the most important factor in determining its quality. However, this is not necessarily true. The key factor in determining the quality of a charge controller is its reliability over time. This means looking at the track record of the controller in real-world projects, and evaluating how well it has performed over the long term.

The current capacity of a charge controller is important, but it is mainly determined by the voltage and power output of the solar panel. A 10A or 15A current capacity is usually sufficient for most outdoor solar lights, and the cost of the charge controller is relatively low compared to other components.

To ensure that you are getting a high-quality charge controller, it is important to do your research and choose a reputable supplier with a proven track record of delivering reliable products. Don’t be swayed by the current capacity alone, as it is not always a reliable indicator of quality.

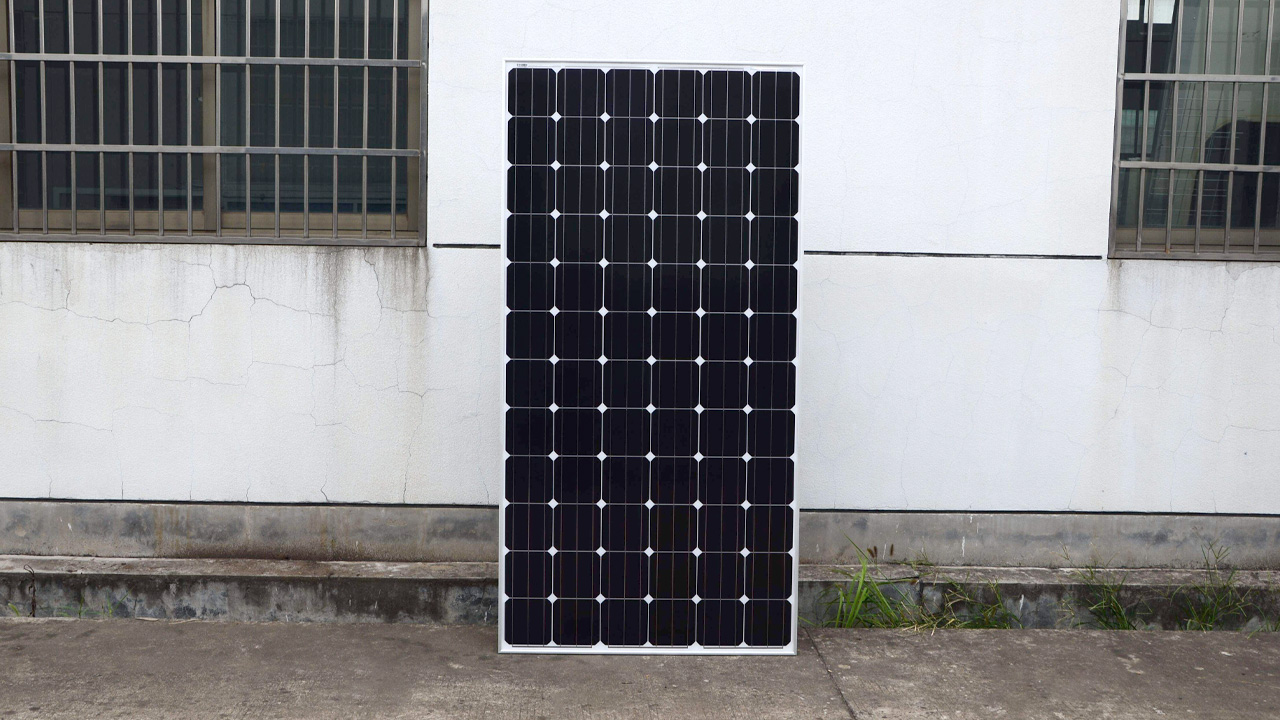

Misunderstanding 4: Solar panel sizes equal to the solar panel power

Some people think that the size of a solar panel determines how much power it can generate. However, this is not always the case. Sometimes, solar street light manufacturers will use fewer solar cells or even broken ones to make their solar panels look bigger than they actually are. This allows them to save money and get more orders, but it can also lead to lower quality and shorter lifespan.

To make sure you get high-quality solar panels for your street lights, we recommend using monocrystalline panels instead of polycrystalline ones. Monocrystalline panels can generate more power than polycrystalline panels, especially on cloudy days. This is important because the lighting time in cloudy weather is a key factor in the performance of street lights. Additionally, monocrystalline panels are typically 20% smaller than polycrystalline panels with the same power output. This makes them easier and safer to install on top of poles.

Misunderstanding 5: Battery capacity is AH

One common misunderstanding is thinking that the battery capacity is only measured in AH (ampere-hours). But we also need to consider the voltage of the battery. For example, a 12V 30AH battery has four times the capacity of a 3.2V 30AH battery.

Smaller solar lights such as solar flood LED lights and solar wall lights often use 3.2V batteries, which are popular on Amazon and eBay. However, low voltage battery systems cannot support high power LED solar lights. This is because a smaller voltage requires a larger current to reach the same power, which can damage the solar charge controller. In our experience, a 3.2V battery system can only support LED power under 20 watts. For higher power applications, we recommend using a 12V battery system, although this requires a more complicated packaging process. Despite the higher cost, a 12V battery system can support higher power LED lights and is a better choice for larger solar lighting applications.

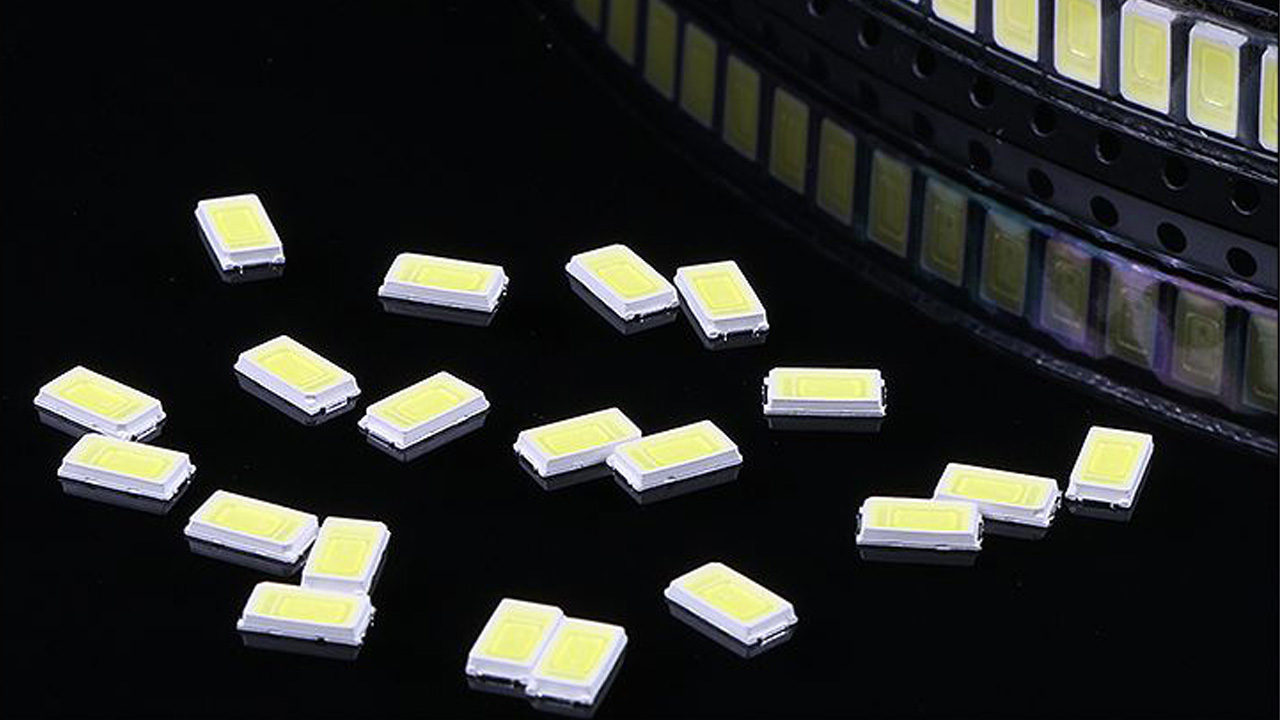

Misunderstanding 6: LED chips are very expensive

It’s important to understand that solar lights have four key components: the solar panel, battery, solar charge controller, and light source. The solar panel converts sunlight into electrical energy, while the battery stores this energy for use when it’s dark. The solar charge controller regulates the amount of energy going into the battery, and the light source provides the actual light.

When it comes to the cost of solar lights, the main expenses are the battery and solar panel. While there is no need to use more expensive monocrystalline solar cells for solar lights, it’s important to note that polycrystalline modules may have lower efficiency and higher production costs.

For batteries, lithium batteries have a longer lifespan and are lighter than lead-acid batteries, but they are also more expensive. However, the cost of batteries is decreasing,and solar charge controllers can help to regulate the brightness of the light, which can also save on the total cost.

Contrary to popular belief, LED chips do not make up a large percentage of the cost of solar lights. In fact, they typically only account for 5-10% of the total cost. To further reduce costs, it’s recommended to use high luminous efficacy LED chips that can provide more than 220 lumens per watt in 0.8 watts per piece. By using these efficient LED chips, it’s possible to achieve the same brightness with lower power usage, resulting in a smaller solar panel and battery capacity, and ultimately, lower costs.

Overall, while the cost of solar street lights has been a limiting factor in the past, the decreasing cost of batteries and advancements in technology are making them more accessible and affordable.

Misunderstanding 7: The sample solar lights work well means Solar street lights quality is good

It is a common misunderstanding to assume that if a sample of solar lights works well, then the quality of the entire batch will be good. However, the solar lighting system is much more complex than regular LED lights, as it includes components such as the solar charge controller and battery. Even if the sample appears to work well, if the quality of these components is not up to par in the mass-produced lights, then the failure rate could be high.

When evaluating the quality of solar lights, there are three key factors to consider: brightness (measured in lumens), lighting time during the night, and performance on cloudy days. The lithium battery is the component that largely determines the lifespan of the solar street lights. If the battery capacity is too small or of poor quality, the lifespan of the solar lights could be less than one year. Therefore, while samples of solar lights may work well for several months, their lighting time may decrease after a year due to the battery’s quality. So it’s essential to look beyond the sample and ensure that the quality of the battery and other components is consistent across the entire batch of solar street lights.